Use of material is possible with active link

© 2015 - 2024. Hunting, Fishing - Information Portal Support the project, donate

Effective range of a magnum cartridge

The issues of Magnum ammunition and range of shot are considered. The history of manufacturing guns under Magnum, tests. Range of shot - myths and reality.

In recent years on the pages of the magazine "Hunting and hunting economy" systematically appears information about hunting rifles and cartridges such as "Magnum". Such rifles initially began to be manufactured in the United States, and then in a number of European countries and Japan, but mainly for the American market. Magnum shotguns are produced abroad mainly in 12, 20 and 410 caliber. As a rule, these are shotguns of reliable modern designs, of high durability, designed for firing heavy shot shells and corresponding to these shells reinforced powder charges. The "Magnum" rifles' chamber is lengthened to 76 mm, and their weight is increased. For example, the weight of 12-gauge Magnum shotguns is 3.4-3.6 kg. Barrels are slightly elongated and are usually produced with full chokes. Magnum shotguns can be fired with both standard ammunition and special cartridges. In USA, 12-gauge Magnum ammunition includes cartridges loaded with 39; 42.5; 46; 49.5; 53 g shot; 20-gauge ammunition is loaded with 32; 33.6; 35.4 g shot. A few years ago, the USA began producing 70mm Magnum cartridges, called "Magnum Small" or "Magnum Short". These cartridges are loaded with 39 and 42.5 g shot shells for 12 gauge.

In order to accommodate the heavy shot projectile in the cartridge, it was necessary to create cartridge cases with thin bottom wads, special polyethylene wads, and special progressively burning powders. They have high power relative to mass and volume. Thus, a 2.2 g charge of Blue Dot powder provides a 42.5 g shot projectile with an initial velocity of 388 m/s, and a 2.49 g charge of powder provides a 53 g shot projectile with an initial velocity of 380 m/s. Due to the progressive combustion of powders for "Magnum" cartridges, the maximum pressure normal for such heavy shot shells is in the range of 600-650 kgf/cm2 for 12 gauge and slightly higher for smaller calibers.

Calculations showed that a 46 g shot shell requires about 3 g of our smokeless Sokol powder to give it an initial velocity of about 380 m/sec. It was not possible to place such amount of powder and shot with polyethylene wadding even in a 76 mm long shell. We had to limit ourselves to 2.5 g of "Sokol" powder and 39 g of shot. In autumn-winter conditions shooting such loads from "Magnum" rifle with 76 mm chamber did not cause any inconvenience, but did not give any special advantages in comparison with standard factory cartridges. In summer, when firing such cartridges, the recoil increased greatly and exceeded the recoil force of the most powerful American factory ammunition with 53 g shot shells. Of course, this is only an isolated case, but it makes one wonder about the suitability of Sokol powder for Magnum cartridges. We have already covered the issue of modern defects in detail ("Hunting and Hunting Economy", 1979, No. 9), so there is no point in returning to it again.

In American factory-fitted cartridges, space for the shot is provided by more powerful (relative to its volume) powders and by wads of special designs. For example, in 12-gauge shot shells of 49.5 and 53 g, the polyethylene wadding is placed on the powder, and the shot is placed in a separate polyethylene split cup without shock absorber. The whole shot shell is placed in such a cup. Thus, the use of "Magnum" shotguns can be positively solved only in case of complex development of shotguns and cartridges for them.

As foreign experience has shown, the creation of the "Magnum" cartridge required the creation of new cartridge cases, new powders and new wads. Taking into account that heavy shot shells can cause pressures exceeding the calculated ones, it is not allowed to experiment with such shells at home, especially with brass casings and with the addition of smoky powder under the primer.

What did Magnum rifles and cartridges give hunters? The first advertisement of "Magnum" cartridges and shotguns for 12 caliber guaranteed killing range on waterfowl game when shooting from barrels with full chokes up to 72 meters. But these claims were not justified. The maximum range of reliable shot was much shorter.

Comprehensive tests of "Magnum" cartridges conducted in the USA showed that the greater the mass of the shot projectile, the more deformed the pellets are at the moment of firing. This is due to the increasing density of the cross-section of the shot shell due to the higher maximum pressure of the powder gases and due to the reduced shock-absorbing properties of the wadding in the "Magnum" cartridges. And with highly deformed shot, the dispersion of the shot sheaf increases. In tests with Magnum cartridges it was found that beyond 36 meters the loss of accuracy with increasing distance was higher than the loss of accuracy with standard cartridges. This was determined as follows: first, a series of 5 rounds was fired at 36 m and the percentage of hits in a circle with a diameter of. 75 cm; then the target was moved back 4.5 m, another series of shots was fired, and so on every 4.5 m to a distance of 63 m. The average accuracy was then determined. After that, the average accuracy of shot hits on the target at each distance was determined.

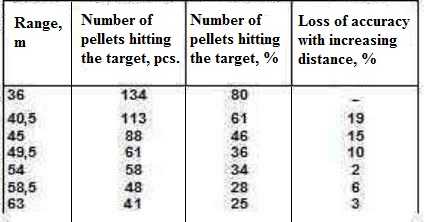

Here is an example of a test of Magnum ammunition with No. 2 shot and a 53 g shot shell:

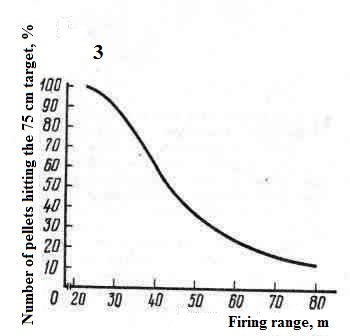

Based on numerous tests, a graph of the loss of accuracy of Magnum ammunition has been plotted.

As can be seen from the above series of tests, the average loss of accuracy from range to range is about 11% (9% for standard ammunition), but at the closest three ranges the loss of accuracy is almost 15%, i.e. the most active dispersion of the shotgun shell occurs here.

The creators of Magnum cartridges thought that by increasing the shot weight from 35.5 g to 42.5 g, they would increase the effective range of game by about 18 meters. In fact, the effective range increased by only 10 meters. This has been convincingly proved by F. E. Sel by numerous series of comparative shootings.

Another American expert, B. R. Hughes, made an interesting experiment. He selected a group of relatively good shooters with Magnum rifles with full chokes, and alternately provided them with Magnum cartridges with the markings obliterated but the shot weight retained. In different sequence, he gave to different shooters cartridges with 53 g, 46 g and 39 g of No. 4 shot. The hunt was conducted on ducks from the tents. Each hunter was accompanied by a huntsman with a rangefinder who measured the shooting range. After the end of the experiment it was found that all cartridges consistently provided a clean hit of ducks up to 50 m. Beyond 50 m, all shooters had wounded ducks. All hunters stated that the best cartridges were those with 46 g shot, the worst - with 53 g. The main dissatisfaction when shooting cartridges with 53 g shot shells was strong recoil.

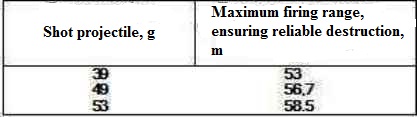

Hughes himself shot several hundred factory-fired Magnum cartridges at targets. He shot No. 4 shot with a shotgun with a full chock, which gave 75% of the shot in a 75 cm circle at 35 meters. After processing the results of the shootings, he obtained the following data on the possibility of reliably hitting game the size of a mallard duck:

Why do the data of shooting at stationary targets not coincide with the real results obtained on the hunt? Because even a very good shooter beyond 50 meters makes mistakes in aiming, which is the reason for a considerable number of shootings.

Hughes came to the conclusion that when used correctly, i.e. when shooting at distances not exceeding 50 meters, the Magnum ammunition significantly reduces the number of wounded shooters, and that this is where the value of such ammunition lies. Shooting with any cartridges beyond 50 m, he recognizes inexpedient and cruelly ridicules braggarts and ignoramuses who assure that they consistently shoot with "Magnum" cartridges at 75-90 m. As measures to combat such grief hunters, he proposes to deprive them of the right to hunt.

Т. Roster, exposing the advertising myth about the incredible range performance of Magnum ammunition, used more than 5,000 rounds of various calibers. He also concluded that the shot sheaf of Magnum ammunition disperses more rapidly than the shot sheaf of standard ammunition. Therefore, he believes that Magnum ammunition is more effective than standard ammunition at ranges of 30-45 meters, but not over 50 meters.

I would like our hunters to learn a lesson from the experience of using Magnum rifles and cartridges and not to consider them as a means of significantly increasing the range. We still have many hunters shooting at game beyond the range of a shotgun. The advent of Magnum shotguns and ammunition should not encourage these unsportsmanlike habits.

Figures:

1. A cartridge with a standard shot shell (1), providing two wads. Second cartridge with a larger shot (2). In order to accommodate the shot, only one wad had to be used. This halves the shock-absorbing properties of the wadding, resulting in increased deformation of the shot. At the moment of ignition of the powder charge (3), the actual combustion chamber is larger in a cartridge with two wads than in a cartridge (4) with a larger shot load but one wad. The larger combustion chamber (3) is achieved by compressing the two wads. Since the actual combustion chamber is smaller with one wad (4) than with two wads, the maximum pressure at the moment of firing is higher in the single wad cartridge. The higher maximum pressure is also due to the energy of the heavier shot projectile. Increased maximum pressure results in increased shot deformation.

2. On the left is a standard Remington (USA) cartridge with a 35.5 g shot shell. On the right is a "Magnum Little" cartridge with a 42.5 g shot shell; both cartridges are 12-gauge. It can be seen from the figure that to accommodate the shot projectile of the Magnum cartridge it was necessary to change the design of the cartridge case wadding and use a new type of polyethylene wadding with much lower shock-absorbing properties compared to the wadding of the standard cartridge.

3. Diagram of changes in the heap factor when firing "Magnum" cartridges of 12 caliber; shot #2.

Range of effective shot. D.Polyakov. Hunting and hunting economy, 1980,12.

1 2