Home >> HUNTINGS GUNS >> Winchester Model 1300, manual

Important instructions for

Winchester®

Model 1300 Shotguns

(Manual)

GUN SAFETY WARNINGS

IT IS ESSENTIAL THAT THESE OPERATING INSTRUCTIONS BE THOROUGHLY STUDIED BEFORE USING THIS FIREARM TO ASSURE PROPER AND SAFE GUN HANDLING. FAILURE TO FOLLOW THESE INSTRUCTIONS OR FAILURE TO OBEY ANY SAFETY WARNING MAY RESULT IN INJURY TO YOURSELF OR OTHERS, OR CAUSE DAMAGE TO YOUR GUN.

As a gun owner, you accept a set of demanding responsibilities. How seriously you take these responsibilities can be the difference

between life and death. There is no excuse for careless or abusive handling of any firearm. At all times handle your shotgun and any other firearm with intense respect for its power and potential danger.

PLEASE READ AND UNDERSTAND ALL OF THE CAUTIONS,

PROPER HANDLING PROCEDURES AND INSTRUCTIONS

OUTLINED IN THIS OWNER'S MANUAL BEFORE USING

YOUR NEW FIREARM.

1. Do not carry a loaded gun with a live round in the chamber while walking, running, climbing a tree, crossing a fence or anywhere you might slip or fall, drop the gun or otherwise bump or jar the gun. A gun that is dropped, bumped or jarred with a chambered

round might accidentally discharge even with the safety on, causing serious injury to you or someone else. When you are ready to shoot and a round is chambered, keep the safety on.

2. Do not rely on the safety to prevent accidental discharge. Many safeties merely block the trigger and prevent firing by pulling the trigger. The safety may not prevent an accidental discharge due to dropping, jarring or bumping a gun.

3. Use only ammunition for which the gun is chambered, as indicated on the barrel, to prevent excessive pressure and possible serious personal injury.

4. Incorrectly reloaded ammunition can cause serious personal injury and damage to the firearm due to excessive pressure. Reload only after proper instruction and in strict compliance with instructions and data contained in current reloading manuals.

5. Never point a gun at anything you do not intend to shoot. Always keep it pointed in a safe direction in case of accidental discharge.

6. Always check to ensure that the barrel is free of obstructions before loading and using the gun. If you experience light recoil or off sound, check the barrel for an obstruction.

7. Before firing, clean any grease or oil out of the barrel with a cleaning rod and patch. Grease or heavy accumulation of oil can cause excessive pressures and result in serious personal injury.

8. Keep barrel, chamber and action free of rust. Rust in the barrel and chamber can cause excessive pressures resulting in serious injury. A rusted, pitted or eroded barrel should be replaced.

9. Use hearing protection to prevent ear damage from repeated exposure to gunfire.

10. Always use proper shooting glasses to prevent eye injury from flying particles.

11. Never carry a loaded gun in a motor vehicle or carry one into a dwelling. Always carefully unload the gun before entering a motor vehicle, a dwelling or an area such as a camp. Always point your gun in a safe direction while loading or unloading to prevent serious injury in case of an accidental discharge. Never load your gun in a house or in a vehicle.

12. Never shoot at a hard, flat surface or at the surface of water to avoid a ricochet and possible serious personal injury to yourself or a bystander.

13. Store guns in a clean dry place out of reach of children and separated from stored ammunition.

14. Never alter any parts of your gun. Any alterations or adjustments that may become necessary to the operating mechanism should be performed by a qualified gunsmith.

15. Hunting from elevated surfaces, such as tree stands, is dangerous. Doing so may increase the risks of handling any firearm. Always make certain that the stand being used is safe, sturdy and stable. Always make certain your firearm is unloaded when it is being taken up and down from the stand. Always make certain that your firearm is not dropped from the stand or dropped while it is being taken up or down from the stand.

Discharging firearms in poorly ventilated areas, cleaning firearms or handling ammunition may result in exposure to lead and other substances known to cause birth defects, reproductive

16. harm and other serious physical injury. Have adequate ventilation at all times. Wash hands thoroughly after exposure.

GENERAL DESCRIPTION Winchester 1300

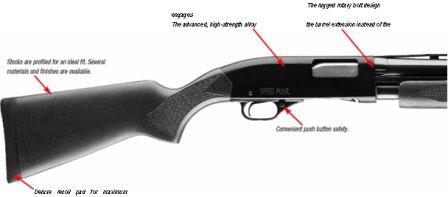

No pump shotgun is faster than the Winchester Model 1300. In fact, the Model 1300 is so fast, we call it the Speed Pump™.

In more ways than one it's "the pump that thinks it's a semi-auto." A fraction of a second after you pull the trigger and fire a Model Winchester 1300, the lugs of the ultra-strong rotary bolt begin disengaging from the barrel extension. Recoil forces still present in the gun then assist the slide rearward. You can feel the slight rearward force on the forearm as you shoot, which makes it much easier to

begin your pumping action. You'll soon find that you will complete the pumping action forward quickly and without conscious effort. In a brief instant you've cycled a shell and are ready for a second shot. Speed like this makes a big difference, allowing you to set up for a second shot more quickly and concentrate on your target - not just on pumping.

With the Model Winchester 1300's rotary bolt design, the lugs engage directly in the lug recesses in the barrel extension. This is an unusually strong, consistent and reliable lockup design. Every design feature of the Model 1300 works together to make what many consider the most reliable pump shotgun on the market today.

Your new Model 1300 is one of a number of different versions and configurations offered. The basic operating procedures are the same for nearly all of them. Where there are differences they are pointed out in this owner's manual for your convenience.

GENERAL OPERATION

The Winchester Model 1300 is a pump action shotgun that allows you to load a round by cycling the action to eject the empty shell, and move an unfired shell from the loaded magazine tube to the chamber. This can be repeated until the magazine is empty. A single round can also be inserted into the chamber manually. The Model 1300 breaks down for easy cleaning and storage.

Prior to using live ammunition, familiarize yourself thoroughly with the operating instructions in this owner's manual. Get accustomed to the feel of your new gun and know the forces required to operate the action. Learn how to pull the trigger and, above all, know the location and operation of the safety. Procedures for disassembly and operation of various components are outlined later in this owner's manual. Please read and study them thoroughly. In addition, always remember:

WARNING: ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION.

USE THE CORRECT AMMUNITION REFERENCED BY THE INSCRIPTION ON THE BARREL.

BEFORE LOADING YOUR GUN BE SURE ALL GREASE AND OIL HAVE BEEN REMOVED FROM THE BARREL AND CHAMBER, AND THERE ARE NO OBSTRUCTIONS.

TERMINOLOGY AND DESCRIPTIONS Winchester 1300

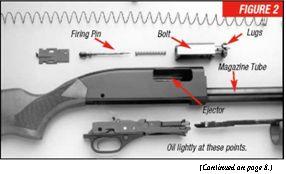

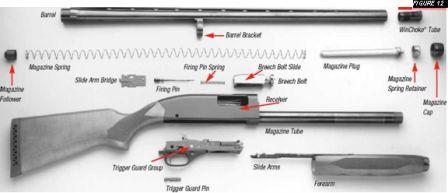

Descriptions in this owner's manual generally refer to the gun in the horizontal position, that is, in the normal firing position. For example, the muzzle is forward or front; the butt stock is rearward or rear; the trigger is downward or underneath; the sight is upward or on top. For general parts terminology, refer to Figure 1.

to the extent necessary in order to follow the instructions contained in this owner's manual (Figure 12). Figure 2 covers the general features and benefits of the Winchester Model 1300 design. Throughout this owner's manual the "action" refers to the mechanism of this shotgun which loads and secures the shells in the chamber.

SERIAL NUMBER

The serial number is located on the left side of the receiver, just above the trigger guard. Record the serial number at the front of this book for future reference.

AMMUNITION

All current 12 and 20 gauge Model 1300s have a 3" chamber and are designed to shoot all factory loads such

as 3" Magnum, 2M" Magnum, 2M" High Velocity, 2M" Field and Target loads. The barrel can safely shoot both lead and steel shot. Special rifled choke tubes and rifled barrels are designed for shooting sabot-type slugs. Winchester ammunition is always an excellent choice for your new Winchester shotgun, delivering unmatched performance and dependability.

MAKE SURE YOU USE ONLY THE EXACT AMMUNITION/GAUGE AS LISTED ON THE LEFT SIDE OF THE BARREL.

WINCHESTER FIREARMS / U.S. REPEATING ARMS CO. CAN ASSUME NO RESPONSIBILITY FOR INCIDENTS WHICH OCCUR THROUGH USE OF CARTRIDGES OF NONSTANDARD DIMENSION OR THOSE DEVELOPING

PRESSURES IN EXCESS OF SAAMI (SPORTING ARMS AND AMMUNITION MANUFACTURERS' INSTITUTE) ESTABLISHED STANDARDS.

DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS OR HANDLING AMMUNITION MAY

RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM AND OTHER SERIOUS PHYSICAL INJURY. HAVE ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS

THOROUGHLY AFTER EXPOSURE.

Incorrectly reloaded ammunition can cause serious personal injury and damage to the firearm due to excessive pressure. Reload only after proper instruction and in strict compliance with instructions and data contained in current reloading manuals.

MAGAZINE CAPACITY Winchester 1300

It is extremely important that you know the magazine capacity of your Model 1300. It is listed on the hangtag supplied with your Model 1300. Under appropriate circumstances - at a range or other suitable shooting location - load your magazine to full capacity and make note of the number of shells. Remember, "total" capacity includes an additional round which can be loaded manually in the chamber in addition to a full magazine.

INITIAL CLEANING/OILING

Some metal parts of your new Model Winchester 1300 have been coated at the factory with a rust preventative compound. Before using your Model 1300, clean the anti-rust compound from the inside of the barrel, receiver, breech bolt mechanism and the action/chamber areas. A high quality, lightweight gun oil should be used to remove this compound and to give your new gun its first lubrication. Clean the barrel using a cleaning rod and patch as explained under "Cleaning and Maintenance Suggestions" found on page 25 in this owner's manual. First lubrication suggestions are outlined below.

Before beginning assembly of your Model Winchester 1300 you should first wipe the mechanism clean and apply a few drops of quality oil on the indicated surfaces (Figure 2).

MODEL Winchester 1300 FEATURES

Choice of barrels. Choose standard ventilated rib models with the WinChoke® system; rifled barrels with rifle sights for shooting slugs; smoothbore barrels with rifle sights; or models with shorter, smoothbore barrels with the WinChoke system.

Faster, inertia-assisted pumping. The rotary bolt disengages from the barrel fractions of a second after the shell fires. The bolt is forced rearward by inertia, actually assisting you as you pump the forearm rearward for the next shot.

Model Winchester 1300 field guns feature a fully floating ventilated rib. On all barrels, as the barrel heats

with shooting, dimensions can vary slightly. The

1300's floating rib design allows the rib to move without distorting your sight plane.

Most Model Winchester 1300 hunting models are fitted with the WinChoke system. It allows you to change choke constriction to the demands of the game being hunted. You can easily change the pattern size and density by simply switching tubes. A variety of accessory choke

tubes are available.

Avoid applying too much oil. Only a light film is necessary. Excessive oil should be wiped off, especially in cold weather.

CLEANING PARTS WITH SPECIAL FINISHES -

Be especially careful when cleaning guns with camouflage, Dura-Touch® Armor Coating and other special finishes. Always prevent these surfaces from coming in contact with cleaning solvents, barrel scrubbers and other strong chemicals. It is preferable to clean these surfaces with a light gun oil containing no solvents or with a damp cloth and mild dish soap (be sure to keep water out of the action). When cleaning your firearm's bore and action, protect the external finishes from any contact with chemicals used. Also, avoid any contact between external finishes and other strong chemicals like those found in DEET-containing insect repellents, sunscreens, etc. Damage to camouflage, Dura-Touch and other finishes caused by chemicals is irreversible and unrepairable.

If your new Model Winchester 1300 is to be stored for an extended period of time, it is permissible to leave the rust preventative compound in place and keep your Model 1300 in its box for maximum protection during long-term storage.

OPERATION OF THE SAFETY Winchester 1300

Your new Model 1300 Winchester shotgun is designed with a cross bolt-type safety. It is located just forward of

the trigger on the trigger guard and is convenient for gloved or ungloved fingers (Figure 4). It is essential that you become very familiar with the feel, look and operation of the safety on this shotgun before attempting to load and shoot.

With the safety in the "on safe" position the trigger and hammer are blocked and the shotgun cannot be fired. In the "off safe" position - if your gun is loaded with a round in the chamber - the chambered round can be fired by simply pulling the trigger.

o "ON SAFE" - The safety button is pushed fully to the right. The red band on the left side is not showing. Always maintain the safety in the "on safe" position (fully on) when a cartridge is in the chamber and until shooting is imminent.

o "OFF SAFE" - The safety button is pushed fully to the left

(Figure 4). A large red band is exposed on the button as it protrudes on the left side of the trigger guard.

CAUTION: THE RED WARNING BAND ON THE SAFETY BUTTON IS FOR CONVENIENCE ONLY. DO NOT DEPEND ON THE RED COLOR ALONE TO INDICATE YOUR GUN'S SAFETY STATUS, AS TIME, EXPOSURE TO THE ELEMENTS, AND THE ABRASIVE ACTION OF CLEANING AGENTS CAN ERASE IT.

Never rely totally on your gun's safety button. It is merely an aid to safe gun handling. Like any mechanical device the safety can possibly fail: it can be jarred or inadvertently manipulated into an unsafe condition. Always keep your shotgun pointed in a safe direction.

At all times in the field keep the safety in the "on safe" position and the barrel pointed in a safe direction. It is a good idea never to load your shotgun until you are in the field and shooting is imminent; or until you are at your station at a range and it is your turn to shoot. For extra safety, and as a courtesy to others, fully unload and place the action in the open position at all times other than when shooting is immediately imminent.

IT IS ESSENTIAL THAT YOU BECOME VERY FAMILIAR WITH THE FEEL, LOOK AND OPERATION OF THE SAFETY ON THIS SHOTGUN BEFORE ATTEMPTING TO LOAD AND

SHOOT IT.

INITIAL ASSEMBLY/TAKEDOWN

ASSEMBLY -

Remove the barrel assembly and receiver/stock section from the carton. Be sure you have wiped them clean and oiled them as explained on page 5. Unscrew the magazine cap from the magazine tube. Because the magazine spring is held in place by a friction-type magazine spring retainer, always be careful which direction the end of the magazine is pointed.

ALWAYS KEEP THE MAGAZINE POINTED AWAY FROM YOU AND OTHERS WHEN REMOVING THE MAGAZINE CAP.

Your shotgun will usually come out of the box with the bolt assembly in the closed position (forward), with the trigger assembly already in place in the receiver. The barrel can be installed with the action closed, but it is easier if the action has been opened slightly.

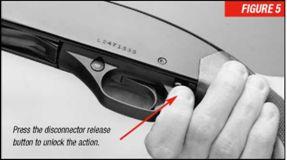

To unlock and open the action without pulling the trigger, push up on the disconnector release button at rear of the trigger guard (Figure 5) on the left side and pull back on the forearm. Once the action is open, perform the following steps:

1. Grasp the barrel ahead of the barrel bracket.

2. Position the barrel over and in line with the magazine tube.

3. Slide the barrel rearward.

4. Guide the barrel bracket over the end of the magazine tube and guide the barrel extension into the receiver. Be sure that the slot in the barrel aligns with the ejector. As a guide in assembly, align the rib on the barrel assembly with the grooves on the top of the receiver.

5. Slide the barrel rearward until it seats in the receiver.

6. Immediately replace the magazine cap. Tighten it hand tight at least three full turns to ensure secure engagement.

TAKEDOWN

FIRST BE CERTAIN THERE ARE NO SHELLS IN THE MAGAZINE OR CHAMBER.

1. Depress the disconnector release button, found behind

the trigger guard on the left side (Figure 5) to unlock the action without releasing the hammer.

2. Open the action and place the safety in the "on safe" position. (The red warning band must not be visible.)

3. With the magazine pointed in a safe direction, unscrew and remove the magazine cap. Be careful, the magazine spring and magazine plug are retained by a friction-type retainer.

AL WA YS KEEP THE MAGAZINE POINTED AWAY FROM YOU AND OTHERS WHEN REMOVING THE MAGAZINE CAP.

4. With one hand, grasp the barrel ahead of the barrel

bracket, hold the buttstock with your other hand.

Pull the barrel to disengage it from the receiver. Slide

the barrel bracket off the magazine. Do not use

excessive force. Immediately replace the magazine cap

and hand tighten at least three turns.

Reassembly of the barrel to the action is explained in the previous section.

LOADING PROCEDURES Winchester 1300

FIRING A SINGLE SHOT -

Use the correct ammunition referenced by the inscription on the barrel. Before loading your gun, be sure all grease and oil have been removed from the barrel and chamber and there are no obstructions.

1. Depress the disconnector release button found behind the trigger guard on the left side. This unlocks the action without releasing the hammer.

2. Open the action and place the safety in the "on safe" position. The chamber is now ready to be loaded.

3. To operate your Model 1300 in a single-shot mode, a shell can now be placed directly into the chamber through the ejection port.

IMPORTANT: WHEN THE SLIDE IS MOVED FORWARD WITH A SHELL PLACED DIRECTLY INTO THE CHAMBER, THE

GUN IS NOW READY TO FIRE.

LOADING THE MAGAZINE -

Before loading, make sure your shotgun is pointed in a safe direction, you are in an appropriate location for loading, and that shooting will be imminent.

1. Place the safety in the "on safe" position and close the action.

2. Depress the carrier with the front of the shell (Figure 6).

3. With your thumb on the base of the shell, push the shell into the magazine until the carrier returns to the original position.

4. Repeat the procedure until the magazine is fully loaded.

WARNING: TO AVOID ACCIDENTAL DISCHARGE, DO NOT

CARRY A GUN WITH A SHELL IN THE CHAMBER.

UNLOADING PROCEDURES Winchester 1300

Perform the following steps to remove shells from the chamber and magazine on all Model Winchester 1300s.

1. Point the muzzle in a safe direction.

2. The safety should be in the "on safe" position (the red warning band will not be visible).

3. Hold the disconnector release button inward to release the slide (Figure 5).

4. Slide the forearm through a complete cycle of the action and repeat the process until all the shells in the magazine have been transferred to the chamber and then ejected.

5. When the last shell in the magazine has been cycled through the chamber and out the ejection port, leave the action open.

6. Using your index finger, feel the entry of the magazine to make sure there are no longer any shells in the magazine.

ALTERNATE WAY TO UNLOAD -

The shells can also be removed from the magazine by following these steps:

1. Place the safety in the "on safe" position, make sure the action is closed and keep the muzzle pointing in a safe direction.

2. Turn the gun over so the trigger guard is facing up, then push the carrier down as far as it will go.

3. Push inward on the right of the cartridge cutoff to release a shell from the magazine (Figure 7). Press the cutoff again to release the second shell. The cartridge cutoff is located on the inside-right of the ejection port. When a shell is in the magazine the cutoff rests on

the brass of the shell.

4. With the safety still in the "on safe" position,

press the disconnector release button and move the

forearm all the way rearward to remove the shell

from the chamber.

WARNING: ALWAYS OPEN THE ACTION AND VISUALLY CHECK THE CHAMBER TO BE CERTAIN THAT YOUR SHOTGUN IS UNLOADED.

FIRING PROCEDURES

1. When you are ready to shoot, with a loaded shell in the chamber, the safety in the "on safe" position, and your finger off the trigger, push the safety to the "off safe" position (with the red warning band fully visible). Your shotgun is now ready to fire with a pull of the trigger.

REMEMBER, THE RECOIL FROM A SHOTGUN, ESPECIALLY WITH MAGNUM LOADS, WILL BE SOMEWHAT HEAVIER THAN MOST OTHER GUNS. FIRMLY SHOULDER YOUR MODEL 1300, TAKE AIM, AND, WHEN ON TARGET, SQUEEZE THE TRIGGER.

2. Pull the forearm fully rearward until the fired shell is ejected out the ejection port.

3. Push the forearm fully forward, transferring a new shell from the magazine into the chamber. Your Model 1300 is again cocked and ready to fire. Immediately put the safety in the "on safe" position (with the red warning band hidden) until you are ready to fire again.

IN THE CASE OF A MISFIRE Winchester 1300

Only rarely will modern factory ammunition experience a misfire. If this ever happens to you when shooting your Model 1300, please follow these instructions carefully.

CAUTION: IN CASE OF MISFIRE, KEEP THE BARREL POINTED IN A SAFE DIRECTION, CAREFULLY OPEN THE ACTION WHILE AVOIDING DIRECT EXPOSURE TO THE BREECH BY YOURSELF AND OTHERS. REMOVE THE SHELL FROM THE CHAMBER. FULLY UNLOAD YOUR SHOTGUN, REMOVING ALL SHELLS FROM THE MAGAZINE.

Carefully inspect the ejected shell. If the primer is indented, the shell should be disposed of in a manner that would prevent accidental injury to you, others, or the environment. If there is no indentation, your gun has malfunctioned and should be serviced by a qualified gunsmith, or by a Winchester Firearms Authorized Repair Center (ARC) (page 27).

WINCHOKE® CHOKE TUBE SYSTEM Winchester 1300

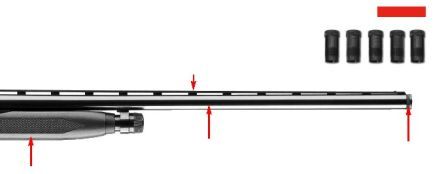

Some Model 1300s are fitted with the interchangeable WinChoke choke tube system. If your shotgun has the words "WinChoke" inscribed on the side of the barrel then you have this system.

The WinChoke system allows you to configure your Model 1300 for the pattern and/or choke constriction your shooting situation demands. It also offers versatility when using slugs or sabots. A variety of WinChoke choke tubes are available for use in your Model 1300, including models designed for use with sabot-type slugs.

Your Model 1300 is provided with the WinChoke screw-in choke tube system. This gives you the finest possible patterns for target and field situations. Plus, it is extremely easy to switch choke constrictions to match your shooting conditions. WinChoke tubes are fully compatible with steel and lead shot. A special choke tube spanner wrench is provided to remove and tighten these tubes.

CAUTION: DO NOT USE WINCHOKE TUBES IN ANY

SHOTGUN BARRELS NOT SUPPLIED BY U. S. REPEATING

ARMS COMPANY (THE MAKERS OF WINCHESTER BRAND FIREARMS). ALSO, DO NOT USE ANY OTHER CHOKING DEVICE IN ANY SHOTGUN BARRELS SUPPLIED BY U. S. REPEATING ARMS. USE ONLY THE APPROPRIATE GAUGE AND TYPE OF CHOKE TUBES MARKED "WINCHOKE" IN

CAUTION: WHENEVER HANDLING ANY SHOTGUN FOR THE PURPOSE OF REMOVING OR INSTALLING A CHOKE TUBE, MAKE ABSOLUTELY CERTAIN THE GUN IS FULLY UNLOADED AND THE ACTION IS LOCKED OPEN. NEVER ATTEMPT TO REMOVE OR INSTALL A SHOTGUN CHOKING DEVICE ON A LOADED FIREARM!

DO NOT FIRE THIS SHOTGUN WITHOUT HAVING THE WINCHOKE CHOKE TUBE INSTALLED. PERMANENT DAMAGE MAY RESULT TO THE THREADS.

Failure to follow these warnings may cause damage to your gun and cause injury to yourself and others.

TUBE REMOVAL -

1. Place the safety in the "on safe" position and fully

unload your Model Winchester 1300.

ALWAYS UNLOAD YOUR MODEL 1300 COMPLETELY. INSPECT THE CHAMBER, MAGAZINE AND FEED MECHANISM TO MAKE SURE THEY DO NOT CONTAIN

ANY SHELLS.

2. Open the action.

3. Use the WinChoke spanner wrench to loosen the tube, turning it counterclockwise (Figure 8). Finger twist the tube the rest of the way out of the barrel.

TUBE INSTALLATION -

1. Place the safety in the "on safe" position and fully

unload your Model 1300.

ALWAYS UNLOAD YOUR MODEL 1300 COMPLETELY. INSPECT THE CHAMBER, MAGAZINE AND FEED MECHANISM TO MAKE SURE THEY DO NOT CONTAIN ANY SHELLS.

2. Open the action and lock it open as explained previously.

3. Before installing a tube, check the internal choke tube threads in the muzzle, as well as the threads on the WinChoke choke tube to be sure they are clean. Lightly oil the threads with a quality light gun oil.

4. Using your fingers, screw the appropriate tube into the muzzle end of the barrel, tapered end first, knurled end outward. When it becomes finger tight, use the WinChoke choke tube spanner wrench to firmly seat the tube (Figure 8). Do not overtighten or forcefully tighten with wrench.

CHOKE TUBES SHOULD BE PERIODICALLY CHECKED TO ASSURE THAT THEY ARE TIGHT AND FIRMLY SEATED. BEFORE CHECKING, FOLLOW THE SAFETY GUIDELINES

OUTLINED ABOVE.

Replacement and additional tubes and wrenches are available from your Winchester firearms dealer.

WINCHOKE CHOKE IDENTIFICATION -

To identify individual WinChoke choke tubes, refer to the abbreviated indications on the outside rim of each tube.

SELECTING THE CORRECT WINCHOKE TUBE -

The WinChoke choke system is fully compatible with factory lead or steel shot loads. The chart at right includes both lead and steel shot information. Lead and steel shot perform differently in tubes with the same choke constriction. For this reason, both lead and steel shot designations have proven necessary. In fact, even larger steel shot diameters result in different patterns than smaller steel shot sizes. Each designation is inscribed on each choke tube.

SPECIAL NOTE ON SHOTGUN SLUGS -

Magazine plug supplied with Ladies/Youth Models

Cylinder or Improved Cylinder WinChokes are suitable for shooting rifled slugs or sabot-type slugs. Never shoot slugs or sabots in any WinChoke barrel with the choke tube removed.

SPECIAL CARE OF CHOKE TUBES AND CHOKE TUBE THREADS -

1. If your gun is equipped with WinChoke choke tubes, do not use a brass brush to clean your gun unless a choke tube is installed in the barrel. Bristles could break off and lodge in the threads, making installation and removal of choke tubes difficult.

2. Regularly remove your gun's tube in order to clean and

oil the threads inside the barrel, as well as on the choke tube itself.

This will protect the threads from being damaged, and also prevent dirt build up that would cause the choke tube to become difficult to remove from the barrel. Clean the threads with solvent and a small, soft brush like a toothbrush. Wipe completely clean and leave a thin film of clean oil on the threads - both on the tube and in the barrel. The threads of the choke tube and the internal threads of the barrel should be cleaned after each use and before the installation of a tube.

3. Be careful when removing or installing a tube. Use the specially designed WinChoke spanner wrench. Damage can result to both the choke tube and the barrel when attempting to remove sticky choke tubes.

4. Never fire your shotgun or run cleaning tools through the barrel of any choke-tubed gun without having a choke tube installed.

REMOVING THE MAGAZINE PLUQ Winchester 1300

When hunting migratory birds, Federal Law mandates the use of a magazine restriction device that only allows a total of three shells to be held in your shotgun at one time.

WHEN REMOVING THE PLUG BE CERTAIN THERE ARE NO SHELLS IN THE MAGAZINE OR CHAMBER, AND KEEP THE BARREL AND MAGAZINE

AT ALL TIMES. REMEMBER, THE PLUG IS UNDER SPRING PRESSURE SO CARE MUST BE TAKEN FOR SAFE REMOVAL. ALWA YS POINT THE END OF THE MAGAZINE AWAY FROM YOUR FACE AND IN A SAFE DIRECTION. ALWAYS WEAR EYE PROTECTION WHEN REMOVING AND REINSTALLING THE MAGAZINE'S THREE-SHOT PLUG.

The magazine plug is spring-loaded and can thrust out of the magazine when the friction-type magazine retainer is removed too quickly. Never look directly into the cap end of the open magazine.

1. Remove the magazine cap.

Place one hand over the retainer and pry it up slowly with a screw driver using your other hand (Figure 9). When the retainer releases you will feel the pressure of the friction ring and plug on the palm of your hand.

3. Slowly raise your hand and let the magazine spring relax. Capture the parts in your hand as they spring out.

4. With the spring relaxed, the friction ring, plug, spring, and follower can be removed. To reinstall, reverse this procedure.

RANGER COMPACT MODELS ONLY -

The Ranger Compact 1300s are specially equipped with a segmented plug that can be cut to adjust the number of shells that can be loaded into the magazine. A full length plug with no segments removed turns this Model 1300 into a single shot when installed into the magazine. As you become more experienced with your Model 1300, the first section of the plug can be cut off at the segment notch allowing one shell to be held in the magazine (Figure 10).

With more experience the other sections of the plug can

be removed to facilitate more shells in the chamber. When the entire plug is removed, four shells can be loaded into the magazine with one also in the chamber.

SIGHT ADJUSTMENTS

Some Model 1300 shotguns are fitted with rifle-type open sights. The style and adjustment system may vary between models and grades. The proper procedure is to shoot a group with the sights set as they come from the factory (intermediate position on both elevation and windage), and then make incremental adjustments to move the sight blade and blade holder to position the group on your target. The procedures below are for the most common type of open sights found on Model 1300 shotguns.

BEFORE MAKING ANY SIGHT ADJUSTMENTS, MAKE SURE YOUR SHOTGUN IS FULLY UNLOADED AND THE MUZZLE

IS POINTED IN A SAFE DIRECTION. PLACE THE SAFETY IN THE "ON SAFE" POSITION.

UPOR DOWN ELEVATION ADJUSTMENTS -

Adjusting elevation on your Model Winchester 1300 requires you to lift up the rear notch blade on your shotgun's rear sight with your fingers and move the notched elevator either forward or backward. To raise point of impact, use your fingers to lift up on the blade and slide the elevator rearward. Adjusting the sight to make your gun shoot lower is just the opposite, move the elevator forward. Remember:

o Move the blade up to shoot higher.

o Move the blade down to shoot lower.

RIQHT OR LEFT WINDAQE ADJUSTMENTS -

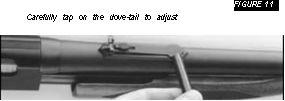

On most Model 1300 sights, the entire rear sight blade holder is dovetailed in the rear sight base. To adjust for windage, gently move the rear sight blade to the right by tapping at the dovetail using a wood dowel or similar material that will not mar the sight (Figure 11). Your gun will now shoot more to the right. Moving the blade holder to the left is just as easily done. Note how much you adjust the sight as you sight-in your Model 1300. Remember:

o Move the rear sight to the right to shoot farther to the right on the target.

o Move the rear sight to the left to shoot farther to the left on the target.

SCOPE BASE MOUNTING INSTRUCTIONS -

Some Model 1300 shotguns are designed to accept a scope or other optical sight; usually these are turkey and deer models. The receiver tops of some of these models are drilled and tapped for scope bases, while some models are equipped with a cantilever scope base. If your shotgun has a cantilever mount, follow the mounting instructions supplied with your scope rings and/or scope. If your shotgun's receiver is drilled and tapped for scope mounts, four holes (in line, in pairs on top of the receiver) will be visible. They are fitted with filler screws. If yours is drilled and tapped you must adhere to the following:

WARNING: YOUR WINCHESTER SHOTGUN IS DRILLED

AND TAPPED FOR THE MOUNTING OF BASES AND RINGS TO ACCOMMODATE AN APPROPRIATE SCOPE OR SIGHT. ALWAYS USE THE CORRECT BASES FOR THIS SHOTGUN WITH THE APPROPRIATE LENGTH SCREWS WHICH ARE AT LEAST "A?" IN LENGTH.

To mount scope bases on your Model 1300 shotgun, perform the following steps:

1. MAKE SURE YOUR SHOTGUN IS COMPLETELY UNLOADED. Check the magazine, chamber and feed mechanism to be sure no shells are present. Leave the action open. Make sure you place your shotgun on a table or other safe/secure location. Protect the finish with rags or other padding.

2. You should have two Model 1300-compatible bases and four screws of at least u/62" in length.

MAKE SURE YOUR BASES ARE COMPATIBLE WITH YOUR MODEL 1300.

3. Clean all oil, grease or dirt from the receiver top and from the scope base parts.

4. Position your shotgun in the upright position with the top of the receiver upward.

5. Remove all four filler screws from the top of the receiver using a very small, thin-bladed gunsmithing-type screwdriver.

6. Pre-position the bases on the receiver top to determine

the best orientation of the bases. Most bases have

transverse grooves cut into them that are offset from

the middle. These are the grooves that the crossbolts

in your scope rings will pass through. The grooves

are offset to allow you to position the bases to fit the design/length of your scope and the placement of the scope front to back for proper eye relief. Place both grooves to the rear, both to the front, or one in each direction, depending on your scope and desired position.

7. Once you know which configuration you will use,

insert the screws through the bases and screw them into

the receiver top using the correct wrench or screwdriver

(usually a 3/s2" hex wrench).

YOU MUST USE SCREWS WHICH ARE AT LEAST "A?" IN LENGTH TO ENSURE PROPER THREAD ENGAGEMENT.

Many gunsmiths find it helpful to use a drop of serviceable thread locking compound to assure the screws stay tight. Make sure the compound does not get into the action.

BE CAREFUL TO ASSURE THAT THE THREADS OF EACH SCREW ENGAGE PROPERLY IN THE THREADS IN THE RECEIVER TO PREVENT STRIPPING THE THREADS IN THE ALLOY RECEIVER. Winchester 1300

8. Tighten the screws snugly, but do not overtighten.

9. Mount your scope rings and scope as outlined in the instructions supplied with your scope rings and/or scope. Always make sure you have the proper eye relief. Always make sure that the saddle crossbolts and the cap bolts are fully tightened before using your shotgun.

One of the advantages of a Model Winchester 1300 is the ability to disassemble the action for cleaning. Under very harsh weather conditions and in dirty environments just knowing that parts are clean and lightly oiled can add an extra measure of confidence to your shooting experience.

Make sure you have a clean place to work and a good place to put the components as they are disassembled (Figure 12).

WEAR EYE PROTECTION AT ALL TIMES. NEVER DISASSEMBLE BEYOND WHAT IS EXPLAINED AND SHOWN IN THIS OWNER'S MANUAL. Winchester 1300

Disassembling the action can be done in the field, but remember there are small parts involved, some of which are under spring tension. First, be certain there are no shells in the magazine or chamber.

REMOVAL OF THE BARREL-

1. Open the action and make sure the gun is unloaded.

2. Close the action and place the safety in the "on safe" position.

3. Unscrew and remove the magazine cap. Remember, always keep the end of the magazine pointed in

a safe direction.

4. Slide the barrel forward, withdrawing the barrel from the receiver and disengaging the barrel bracket from the front end of the magazine.

5. Immediately screw the magazine cap back onto the magazine.

REMOVAL OF THE TRIGGER GUARD GROUP FROM THE RECEIVER -

Removing the trigger guard group is another necessary procedure in performing thorough maintenance of your

shotgun. It is easy to do, and removing it allows you to perform cleaning and maintenance whenever and wherever required. With both the trigger guard group and bolt assembly removed, it is easy to wipe out any debris or moisture that sometimes accumulates in the receiver. The trigger guard group should be removed before you attempt to remove the bolt assembly.

1. Make sure the gun is completely unloaded as explained previously in this owner's manual.

2. Cycle the action by sliding the forearm rearward and then forward. This puts the hammer in the cocked position. Place the safety in the "on safe" position.

3. If the barrel assembly has been removed, always be sure to replace the magazine cap on the end of the magazine tube to prevent accidental disengagement of the magazine spring retainer.

4. Place your gun with the trigger guard facing up on a suitable surface that will protect the receiver finish and stock.

5. Remove the trigger guard pin by pushing it out from the LEFT side of the receiver, the side opposite the ejection port. Any sturdy pushing tool that is smaller in diameter than the pin and will not mar the finish is acceptable. Make sure you can maintain a good grip on the pushing tool and on your shotgun while you push.

6. Push the pin through sufficiently until it can be grasped with your fingers. Pull it the rest of the way out. If it cannot be removed with fingers, make sure your pushing tool or punch has a diameter small enough so that it will push the pin completely through without the tool damaging the hole.

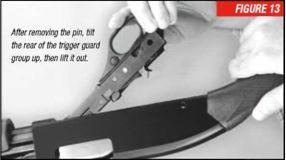

7. With the pin removed, lift the trigger guard group out of the receiver by lifting upward and pulling rearward (Figure 13).

DISASSEMBLY OF THE SLIDE AND BREECH BOLT (12 GAUGE ONLY) -

1. Remove the barrel and trigger guard group as explained earlier, but do not replace the magazine cap.

2. With the action slide arms still attached to the slide arm bridge, simultaneously slide both assemblies forward and out of the front of the receiver. Note that as the breech bolt assembly passes by the ejection port, there may be some resistance from the ejector spring. Carefully work it past the resistance.

DISASSEMBLY OF THE SLIDE AND BREECH BOLT (20 GAUGE ONLY) -

This procedure is necessary because the bolt will not extract out through the front of the receiver as it does on the 12 gauge model.

1. Remove the barrel and trigger guard group as explained earlier, but do not replace the magazine cap.

2. You must disengage the slide arms from the slide arm bridge. Remove the slide arms through the front of the receiver. Remove the bolt slide assembly through the trigger guard group opening.

REMOVAL OF THE FIRING PIN -

Begin with the breech bolt assembly removed from the gun.

1. Grasp the breech bolt assembly, bottom side up (flat side), and push the rear of the firing pin forward with your forefinger. While holding the firing pin in this position, take your other hand and tilt the front end of the slide arm bridge and move it slightly forward. Lift

up on the slide arm bridge and disengage the curved tongue on the slide arm bridge from the groove in the firing pin. This will detach the slide arm bridge from the breech bolt slide.

2. The firing pin is under spring tension and will snap out the rear of the breech bolt when your forefinger releases it. Control the pin as you remove the firing pin and spring.

For cleaning purposes no further dismantling is necessary or recommended. Do not disassemble your Model 1300 further than shown in Figure 11 shown on page 20. Doing so may void your warranty. For repairs that require further disassembly contact a Winchester Firearms Authorized Service Center or a qualified gunsmith as explained under "Parts, Service, Repair and Questions" on page 27.

REASSEMBLY OF THE FIRING PIN, BREECH BOLT AND SLIDE (12 GAUGE ONLY) -

1. Reinstall the firing pin spring over the firing pin. Either end of the spring can go on first.

2. Insert the firing pin/spring assembly into the rear opening of the bolt slide, pin end first.

3. To reinstall the bolt assembly on the slide arm bridge, push or compress the "knob end" of the firing pin sufficiently into the hole in the bolt slide so that the large space between the grooved "knob" and the flange

on the firing pin is centered in the round hole in the bolt slide.

4. Place the curved tongue, located on the slide arm bridge, into the space between the knob and flange and slowly release pressure on the end of the firing pin. Let the flange on the pin pull the tongue toward the rear of the bolt assembly. This should hold the breech bolt assembly and the slide arm bridge together during further assembly.

5. With the firing pin and breech bolt now assembled, engage the slide arm bridge into the matching cuts on the slide arms (Figure 14).

6. Hold the slide arms and bolt/slide arm bridge assemblies together. Start the forearm assembly onto the magazine tube.

7. Remove the magazine cap and carefully guide the slide arms and bolt/slide arm bridge assemblies into the front of the receiver. As the assemblies enter the receiver, slide them fully rearward (Figure 15).

REASSEMBLY OF THE FIRING PIN, BREECH BOLT AND SLIDE (20 GAUGE ONLY) -

1. Reinstall the firing pin spring over the firing pin. Either end can go on first.

2. Insert the firing pin and spring into the rear opening of the bolt slide, pin end first.

3. To reinstall the bolt assembly on the slide arm bridge push or compress the "knob end" of the firing pin sufficiently into the hole in the bolt slide so that the large space between the grooved "knob" and the

flange on the firing pin is centered in the round hole in the bolt slide.

4. Place the curved tongue, located on the slide arm bridge, into the space between the knob and flange and slowly release pressure on the end of the firing pin. Let the flange on the pin pull the tongue toward the rear of the bolt assembly. This should hold the breech bolt assembly and the slide arm bridge together during further assembly.

5. With the trigger guard group removed, insert the bolt assembly through the trigger guard opening up into the receiver. The front face and extractor of the bolt assembly should be facing the barrel or front of the shotgun. The slide arm bridge should be facing down toward the trigger guard group opening.

6. While holding the bolt assembly in place, insert the slide arm bars into the breech and connect them to the slide arm bridge.

REINSTALLATION OF THE TRIGGER GUARD GROUP -

Be careful when reinstalling the trigger guard group. Never force parts into position. The bolt assembly, slide arms and barrel should be attached before installing the trigger guard group. The hammer should be in the cocked position and the safety in the "on safe" position. Carefully insert the trigger guard group into place. It may be

necessary to slide the forearm into different positions until the trigger guard group fits flush into the receiver. When properly installed it will fit easily and the pin will slide in without excessive force. Installing the bolt assembly after the trigger guard group is installed should not be attempted. Consequently, make sure you have already installed the bolt assembly before installing the trigger guard group.

It is not necessary that the barrel already be attached to install the trigger group. Install the trigger group as follows:

1. Turn your shotgun over with the open bottom of the

receiver facing upward. Hold the trigger guard group

at an angle to the receiver (about 45 degrees) and then engage the front tabs on the trigger guard group with the corresponding slots in the magazine throat at the forward end of receiver opening as shown earlier in Figure 13.

2. Rotate the trigger guard group towards and into the receiver opening, until it is parallel with the receiver.

3. Align the trigger guard group with the hole in the receiver and install the trigger guard pin from the RIGHT side of the receiver (ejection port side) until it is flush with both sides of the receiver. The pin should pass through easily with little force. If significant resistance is felt, remove the trigger group and repeat step one.

Your Model 1300 shotgun is now fully assembled. Immediately confirm that the safety is in the "on safe" position. Take time to wipe down and clean all external surfaces as explained under "Cleaning and Maintenance Suggestions" below.

CLEANING AND MAINTENANCE SUGGESTIONS

Your Model 1300 will function better and more reliably over a longer period of time if it is properly maintained and kept clean.

BEFORE PERFORMING ANY CLEANING PROCEDURES, ALWAYS MAKE CERTAIN THERE ARE NO SHELLS IN THE CHAMBER, MAGAZINE OR ACTION/FEED AREAS.

You should clean your Model 1300 after every day of shooting and more often if it becomes excessively dirty.

A minimum cleaning includes wiping down the action and oiling key parts. Most regular maintenance will also include cleaning the barrel. If you encounter a function problem (tight action when working the forearm) be sure to give your gun a thorough cleaning to see if it solves the problem before seeking the services of our service facility or a competent gunsmith. To clean your firearm, adhere to the following general guidelines.

CLEANING PROCEDURES -

ALWAYS PLACE THE SAFETY IN THE "ON SAFE" POSITION BEFORE BEGINNING ANY CLEANING PROCEDURE AND BE CERTAIN YOUR GUN'S CHAMBER AND MAGAZINE ARE UNLOADED.

ALWAYS WEAR PROTECTIVE SAFETY GLASSES DURING ALL CLEANING PROCEDURES. KEEP AMMUNITION AWAY FROM THE CLEANING AREA. DO NOT TEST THE FUNCTION OF YOUR FIREARM WITH LIVE AMMUNITION.

1. Use a cleaning rod with a tip and patch suitable for the size of your Model 1300's bore. Make sure the patch is large enough for a snug fit in the bore. Insert the rod and patch into the barrel at the receiver end and run it back and forth several times.

2. Inspect the chamber and bore for lead and powder fouling. A normal amount of powder residue can be expected and is not serious. It can usually be removed by repeating step one, using a patch saturated with solvent. If fouling should become heavy, it can be removed with a brass bore brush. Dip or spray the brush with solvent and scrub the chamber and bore until the fouling is removed. To prevent brass bristles from breaking off, the brush should be pushed completely through the bore before being withdrawn.

3. After fouling has been removed the bore should be wiped dry. Then pass a lightly-oiled patch through the bore for preservation. A fine, light gun oil is recommended.

4. Wipe all exposed metal surfaces of the receiver, forearm and barrels with a clean rag. Finger marks should be removed because they provide a place where moisture can accumulate. Any dried oil in the receiver area should also be removed.

5. Lightly oil your gun at the points described under "Initial Cleaning/Oiling" found on page 5. Ordinary good judgment will, of course, indicate that the metal of the gun should receive a light film of oil any time the gun has been exposed to weather or handling. This is very important and must be done with every firearm - even stainless steel models. Remember, the polished, finely fitted surfaces of the receiver and action mechanisms must always have a thin film of oil. Make sure that the surfaces of the locking pin system and the hinge components are especially clean and lightly oiled with a high-quality gun oil.

6. INSPECT THE BARREL AND CHAMBER. MAKE CERTAIN THAT NO PATCHES HAVE BEEN INADVERTENTLY LEFT IN THEM. REMOVE ANY THAT REMAIN.

7. Wipe all wood surfaces with a soft cloth.

8. When transporting only, store your Model Winchester 1300 in a quality protective case to prevent scratches and dents. Store in a dry place to prevent corrosion. Store away from children.

MAKE SURE YOUR SHOTGUN IS UNLOADED AND ALWAYS STORE AMMUNITION SEPARATELY.

DO NOT TAKE YOUR GUN'S ACTION OR TRIGGER GROUP APART BEYOND WHAT IS EXPLAINED IN THIS MANUAL Winchester 1300

Your Model 1300 is a specialized, finely-fitted mechanism. You may permanently mar it by attempting to disassemble the inner mechanism assemblies. If further disassembly for service or cleaning is required, take your gun to a Winchester Firearms Authorized Service Center or a qualified gunsmith as explained under "Parts, Service, Repair and Questions" on page 27.

OTHER CLEANING SUGGESTIONS -

o Never pour large quantities of oil into the receiver or other parts. It can drain down to the wood and soften it, causing permanent damage and loosening of the stock.

o After extended periods of heavy use, your gun should be taken to a qualified gunsmith to have the action disassembled for professional cleaning and lubrication.

CLEANING PARTS WITH SPECIAL FINISHES -

Be especially careful when cleaning guns with camouflage, Dura-Touch® Armor Coating and other special finishes.

Always prevent these surfaces from coming in contact with cleaning solvents, barrel scrubbers and other strong chemicals. It is preferable to clean these surfaces with a light gun oil containing no solvents or with a damp cloth and mild dish soap (be sure to keep water out of the action). When cleaning your firearm's bore and action, protect the external finishes from any contact with chemicals used. Also, avoid any contact between external finishes and other strong chemicals like those found in DEET-containing insect repellents, sunscreens, etc. Damage to camouflage, Dura-Touch and other finishes caused by chemicals is irreversible and unrepairable.

PARTS, SERVICE, REPAIR AND QUESTIONS Winchester 1300

If your Winchester rifle or shotgun should ever need service or repair, it is often best to utilize one of our Authorized Service Centers. In some cases it is appropriate to use the Winchester Firearms Service Center in Arnold, MO. A list of Authorized Service Centers was included with your new firearm. If you need a new listing, call us. We can help you determine the best place to service your firearm.

In order to avoid delays, it is important to obtain direct authorization from one of our service specialists before sending your firearm to our facility. This avoids possible delays in obtaining service. Call us for complete details on how to receive service before sending your gun.

Parts listings, Service Center lists, service procedures and general product information are also found on the Web at www.winchesterguns.com.

GENERAL PRODUCT AND HISTORICAL QUESTIONS - Winchester Firearms

275 Winchester Avenue Morgan, UT 84050-9333 1-800-945-5237 (toll free)

PARTS, SERVICE, REPAIR STATUS AND TECHNICAL QUESTIONS -

Winchester Firearms Parts and Service

3005 Arnold Tenbrook Road

Arnold, MO 63010-9406 1-800-322-4626 (toll free)

CAUTION: PARTS ARE MADE FOR WINCHESTER BRAND

GUNS MANUFACTURED BY OR FOR WINCHESTER

FIREARMS / U.S. REPEATING ARMS COMPANY, INC., AND SHOULD NOT BE USED IN OTHER GUNS, EVEN THOUGH MODELS MAY BE SIMILAR. IMPROPERLY FITTED PARTS MAY BE DANGEROUS.

WEBSITE INFORMATION

Winchester Firearms offers an information resource for you on the World Wide Web.

o List of Authorized Repair Centers.

o Customer Service information.

o Answers to many technical and historical questions.

o Links to helpful sites.

Go to: www.winchesterguns.com

Video. Winchester 1300:

Use of material is possible with active link

© 2020-2023. Hunting, Fishing - Information Portal